Dell

Last year Dell showed off Concept Lunaa laptop that could be completely disassembled with just a screwdriver. It was an impressive demonstration of the principles of the right-to-repair movement: modularity, sustainability, and easy access. After tweaking the design for a year, Dell’s back with a second revision. And this one might just change the way you think about electronics repair.

Michael Crider/IDG

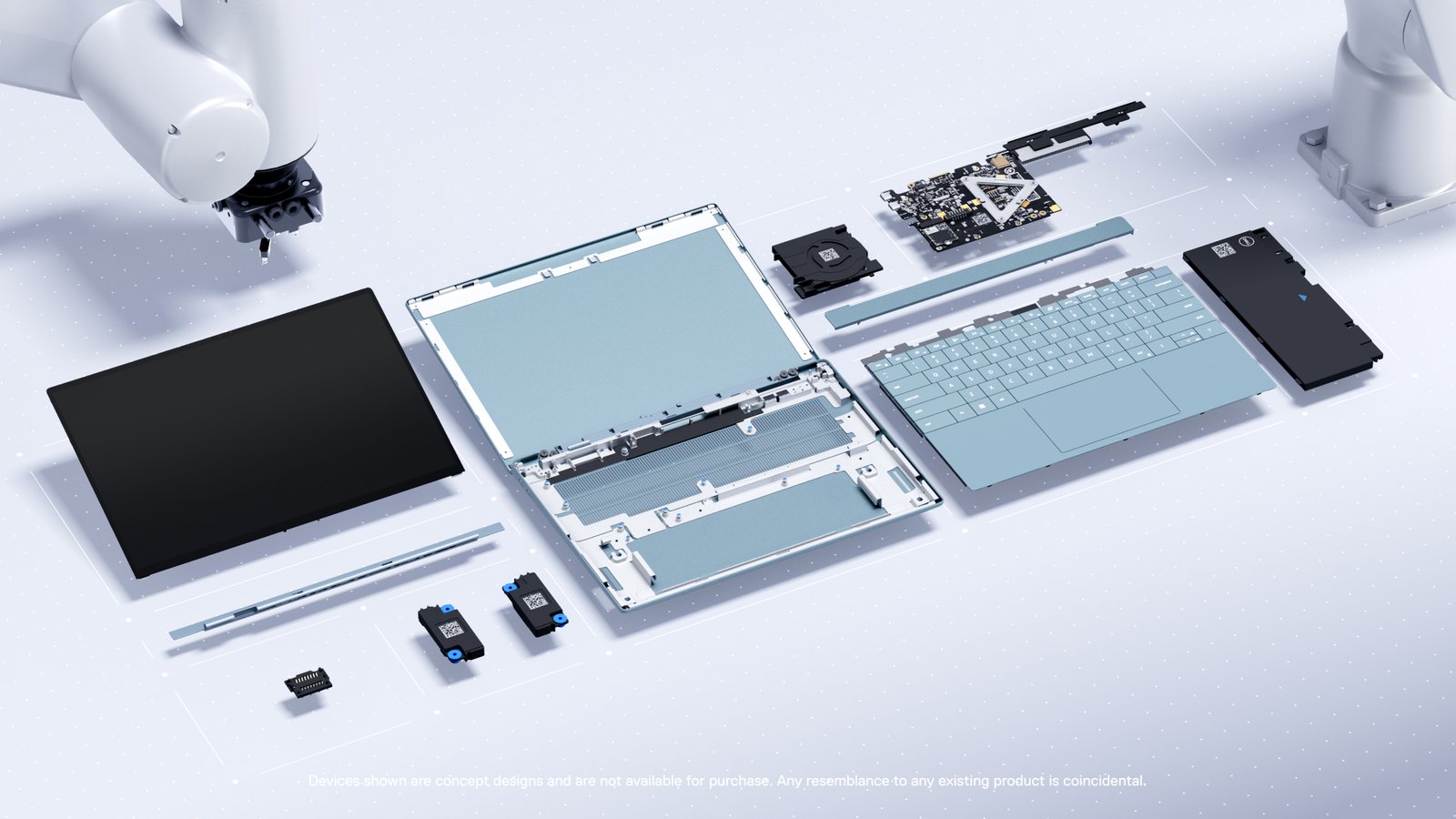

The second revision of Concept Luna works along the same lines, but it requires only a single push-bar tool to take apart. Once the pin hidden inside the Kensignton lock port is released, the user can take apart every component inside by hand. First a retention piece above the keyboard is pulled out, then the keyboard and trackpad assembly. At this point you have access to the motherboard, cooling fan, battery, and two speakers, all of which are modular and sequential. You can pull them all out and replace each component—it’s almost as easy as playing with LEGOs. The screen assembly is a little trickier with a pressure point built into the hinge, but the LCD also comes out and can be easily replaced.

Dell

A Dell engineer showed us how every modular component could be removed, going in sequence, in less than a minute. It’s an impressive process, starting with an ordinary-looking laptop you might see on a Best Buy shelf and ending with a series of modular components. Then it all goes in reverse, ending with a fully booting Windows laptop. It reminded me of Forest Gump assembling and disassembling his rifle.

Michael Crider/IDG

It all relies on a system of communication pins and a sequential design: Each one needs to come out in a specific order and go back in reverse order, kind of like a Transformer toy’s instructions. While this makes getting to specific components a little more time-consuming, it makes the end result “idiot-proof.” You can’t progress to the next component until the correct one is in place, and it’s basically impossible to reassemble the entire laptop incorrectly. Failsafes in the boot process make sure that nothing has been assembled out of order, and it also runs security checks on the components.

The benefits of a Luna-type design are obvious. Individual components could be replaced in a few minutes, even by a novice at home. Upgrades would be just as fast, but the only major components that could really be upgraded in this design are the motherboard (with storage, RAM, and processor embedded) and the screen panel. This is one disadvantage versus a conventional design—for example, you can’t replace just the wireless card, you’d need a full motherboard assembly.

Michael Crider/IDG

Almost as impressive as the design itself is the boon to automated repair and replacement. At its showroom in New York, Dell showed off a repair robot replacing the motherboard of a Luna independently. A machine about the size of an office cubicle could identify the faulty component, bring a fresh part in, disassemble the laptop, replace the part, and re-assemble it in about three minutes. That could drastically reduce repair times for customers.

Even after a year of development, Luna is still in the very early stages. It’s about as basic as a laptop design can get, and while the techniques Dell is developing in this project are certainly being applied elsewhere in the supply chain, the engineers told us not to expect anything like the full Luna design to appear before 2030.

Dell

In the meantime, Dell and other manufacturers are at least attempting more repair-friendly designs for laptops and other machines. Framework’s modular laptop design is about as close as you can get today: it’s much more complex and less user-friendly, but it’s delivering near-universal upgrade and repair options in a conventional laptop form factor.